Indigo Damp Stop 2K (Protect Plus): The Ultimate Two-Component Anti-Dampness Solution

Rising damp, blistering paint, and unsightly salt patches (efflorescence) are common problems in buildings. Indigo Damp Stop 2K (Protect Plus) is the professional-grade, two-component (2K) solution engineered to provide an impermeable, negative-side waterproofing barrier against severe moisture and salt attack. It is designed to be applied on the internal face of damp walls, stopping moisture from penetrating the surface.

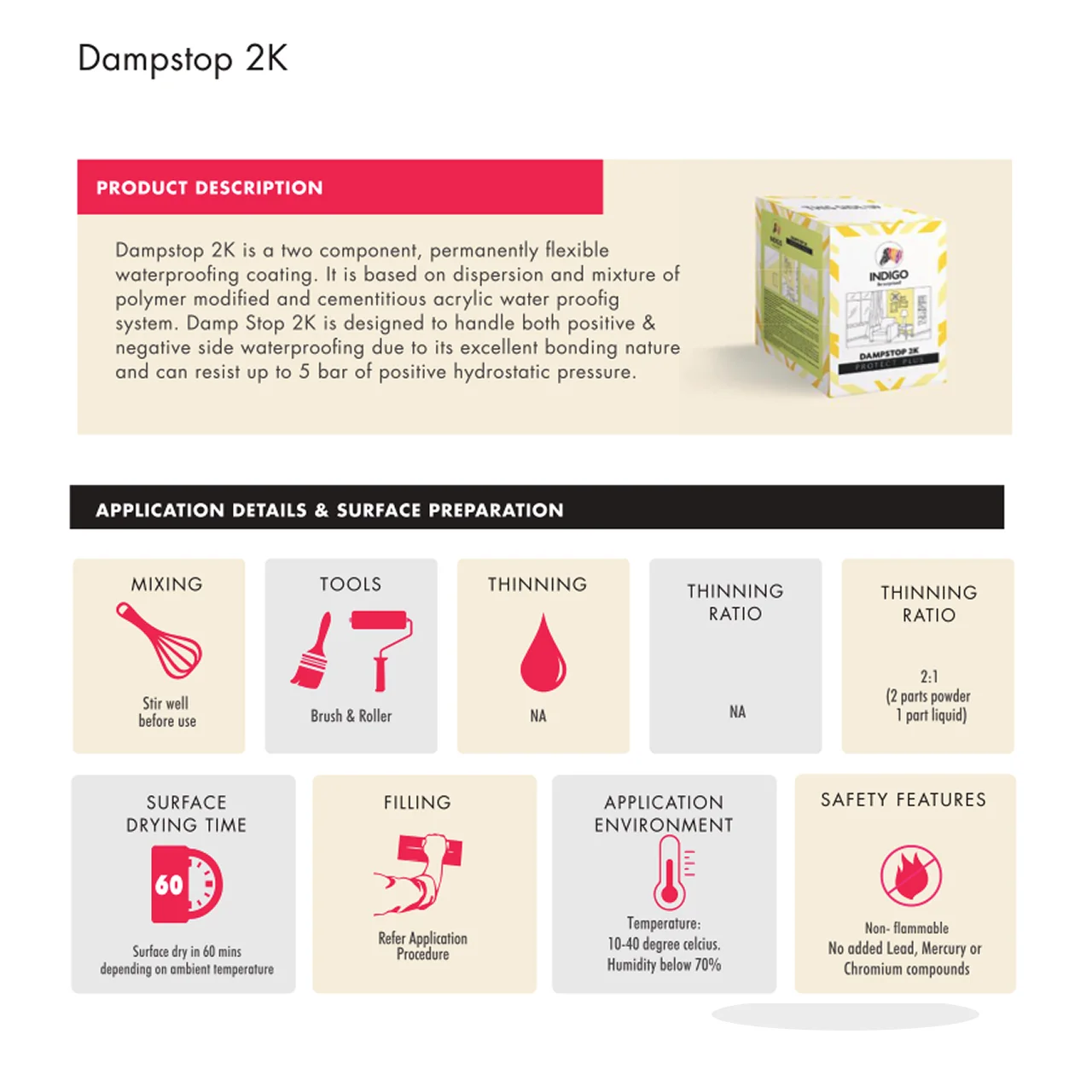

Unlike single-component waterproof coatings, Indigo Damp Stop 2K utilizes a cementitious powder mixed with a liquid polymer. This chemical reaction creates an exceptionally hard, durable, and non-porous film that adheres strongly to masonry surfaces, effectively holding back moisture and high hydrostatic pressure from reaching the final paint coat.

Why Choose Indigo Damp Stop 2K?

When battling continuous dampness, a single coat often fails. This 2K system offers:

- Negative Side Protection: Can be applied directly on the interior wall surface (negative side) to block moisture coming from the outside (positive side).

- High Hardness: The 2K composition provides superior tensile strength and abrasion resistance, making it suitable for subsequent plastering or putty application.

- Anti-Efflorescence: The dense structure prevents soluble salts from migrating to the surface, stopping the formation of white, flaky patches.

- Excellent Adhesion: Forms a powerful mechanical and chemical bond with concrete, brickwork, and plaster.

Key Features of Indigo Damp Stop 2K (Protect Plus)

- Type: Two-Component (Cement + Polymer Liquid).

- Usage: Interior and Exterior damp walls, and negative-side waterproofing.

- Damp Protection: Stops severe moisture and salt damage.

- Preparation: Requires thorough mixing of the two components.

- Paintable: Can be finished with plaster, wall putty, and standard paint systems.

Recommended Application Areas

This cementitious damp-proofing coat is essential for:

- Basement Walls: Where moisture and hydrostatic pressure are highest.

- Ground Floor Walls: Battling rising dampness and capillary action.

- Internal Damp Walls: Where external access for repair is not possible.

- Terrace Parapet Walls: As a primary barrier before plastering.

Technical Specifications: Indigo Damp Stop 2K

| Feature | Details |

|---|---|

| Type | 2-Component (Cement + Liquid Polymer) |

| Mixing Ratio | Powder : Liquid = Approx. 3:1 (By Weight) |

| Usage | Interior & Exterior (Negative & Positive Side) |

| Application | Brush/Roller |

| Drying Time | Surface Dry: 4-6 Hours | Recoat: 6-8 Hours |

| Pot Life | Approx. 1-2 Hours |

How to Apply Indigo Damp Stop 2K

The two-component mixing is critical for activation:

- Surface Preparation: Remove all loose paint, plaster, or efflorescence. Sand with sandpaper or wire brush to expose sound masonry. The surface should be saturated with water, but free of standing water.

- Mixing (Crucial): Pour the liquid polymer component into a clean bucket. Slowly add the cementitious powder component while continuously mixing with a low-speed electric mixer until a lump-free, uniform slurry is achieved. Only mix the amount you can use within the pot life.

- Application (1st Coat): Apply the first coat immediately by brush or roller, ensuring deep penetration into the pores. Apply perpendicularly to the expected second coat.

- Second Coat: Apply the second coat after 6-8 hours (when the first coat is dry, but before 24 hours). Do not sand between coats. Properly treating the source of dampness is essential for product longevity.

- Curing: Cure the surface by misting with water 2-3 times a day for the next 2-3 days.

Frequently Asked Questions (FAQ)

Q: Can I apply putty directly over Damp Stop 2K?

A: It is recommended to apply a thin layer of fine plaster or a thin skim coat of cement putty over the Damp Stop 2K before proceeding with acrylic putty or the final paint system to ensure a flawless finish.

Q: Does this stop water leaking from the roof?

A: While it’s excellent for walls, for large areas like terraces and roofs, use specialized elastic roof waterproofing coatings designed for expansion and contraction.

Q: Is mixing ratio important?

A: Yes, extremely. The ratio (3:1 powder:liquid) is vital for the chemical reaction that provides the product’s ultimate strength and impermeability. Do not deviate from the specified ratio.

Reviews

There are no reviews yet